Expansion Joint Bearings

United executes projects for Railway and Road Bridges giving complete start to end solution. We have complete assembly line to execute the project in stipulated time frame with well qualified and experienced staff. Key strength being one of the premier fabrication shops equipped with high performance machines & tools offering wide range of services.

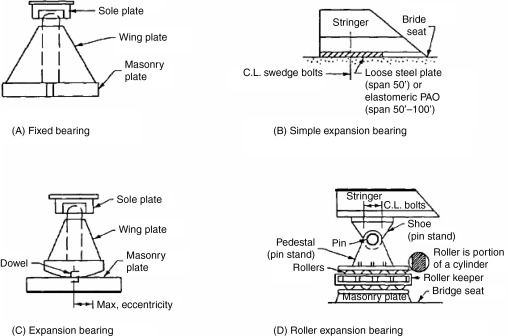

A bridge bearing is a component of a bridge which typically provides a resting surface between bridge piers and the bridge deck. The purpose of a bearing is to allow controlled movement and thereby reduce the stresses involved. ... The oldest form of bridge bearing is simply two plates resting on top of each other. Bearing used in the construction of bridge structure is divided into two major categories namely expansion bearings and fixed bearings. The former permits both translational and rotational movements whereas the latter allow rotational and limited translational movements.

The production shop in- house facilities as mentioned:

- Total Plant Area- 96, 000 Sq. Ft, Area under EOT Cranes- 90, 000 Sq. Ft.

- Max. Lifting Capacity- 80 MT Single Job

- Shop Bay Size- 48 Meters (L) X 18 Meters (W) X 18 Meters (H- Under Hook)

- CNC Oxy/ Plasma, Pug Cutting Machines.

- Submerged Arc Welding Machines.

- Radial Drill & Magnet Drill Machines.

- End Milling Machines.

- Shot Blast Plant- Shot Blasting to prepare the surface for paint adherence.

- Metalizing- Spraying Molten Metal on cleaned steel, providing protective coating.

- Paint Shop- Painting as per customer’s specification & requirement.